Cryogenic Ball Valve Double Block and Bleed -196C Cryogenic Service

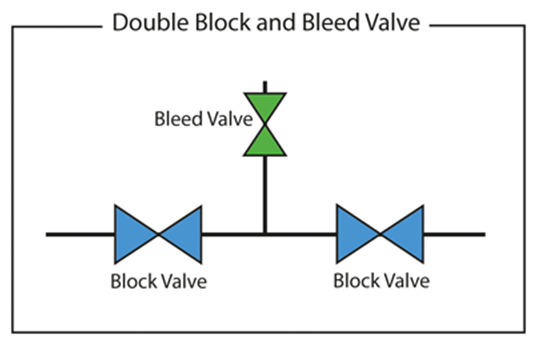

The ball valve double block and bleed is DBB ball valve for the cryogenic service working condition.

It has compact structure for designed two balls in union body, require less assembly space,at the same time and satisfying double-isolation requirements in special process for safety management systems. Compared with multiple valve combine installation,this valve more efficient.

The DBB ball valves provide from upstream to downstream zero leakage performance. This valve can isolate piping on both sides of the valve to vent or bleed the valve cavity between the seats. It is the used in the critical isolation in a variety of applications and markets, such as liquefied natural gas, petrochemical industry,transmission and storage, natural gas industrial processes, main and manifold valves in liquid pipelines, and refined product transmission pipelines.

● Cryogenic service -196℃

● Three valves in single one compact body

● Less leak point Less installation place

● Permit integrity check of seat seals

● Prevent product contamination

Fig. double block and bleed valve system

ARAN offers a wide range of DBB valve types and options to fit specific needs, the valve materials/ends/service condition all can be customized. Your are offer details for our sales engineer to choose correct model for you.

Application

ARAN Cryogenic ball valves designated in highest performance and produced in strictest quality, can meet the highest standard cryogenic service,and wildly applied for safety transportation for processing,storage,shipment and distribution of ethylene,Liquid Nitrogen, Oxygen, LPG, Liquefied Natural Gas (LNG) and other low temperature liquefied gases.

As an efficient and storable clean energy, LNG has shown broad development prospects in all aspects of the industrial chain. Cryogenic ball valve is most demanding valve in the cryogenic liquid storage and transportation equipment system. It has the advantages of flexible switching, reliable sealing, safety and stability etc.

Crygenic Treatment And Test

The valve parts for cryogenic service need do the cryogenic treatment to make sure the valve material performance will suitable for low temperature.

The cryogenic treatment is the process of putting valve parts to low temperatures by medium nitrogen -196 ℃ in order to remove residual stresses and improve wear resistance in steels.

ARAN cryogenic treatment for ball valve part and cryogenic test for finished valve .

| Production Range | Cryogenic ball valve double block and bleed |

| Size | NPS 1/2″~8″ (50mm~200mm) |

| Pressure | ASME Class150~600LBS (PN16~PN100) |

| Production Standards | API/ANSI/ASME/EN/DIN/BS/GB/GOST |

| Design & MFG code | BS6364/ SHELL SPE 770200 Low temperature valveAPI 6D/ASME B16.34 /ISO17292/ ISO 14313/BS5351 |

| Face to Face | ASME B16.10,EN558 |

| End Connection | FLANGE RF/RTJ ASME B16.5/EN1092-1/GOST 33259 ;BUTT WELD BW ASME B16.25 |

| Test & Inspection | ISO 15848/SHELL SPE 77/312 Low temperature leakage testAPI 598, API 6D,ISO5208/ISO 5208/EN12266/GOST 9544 |

| Material code | Low Temperature Carbon Steel -40℃ (ASTM A350 LF2/LF3, ASTM A352 LCB/LCC)Low Temperature Carbon Steel -101℃ (ASTM A350 LF3, ASTM A352 LC3)Stainless steel -196℃ (ASTM A182 F316/F316L/F304/F304L DUAL GRADE, ASTM A351 CF8M/CF3M,CF8/CF3) |

| Operation | Manual, Worm Gearbox, Pneumatic actuator, Electric actuator,Hydraulic-electric actuator |

| Special design | Cryogenic ball valves |

| low temperature to -196 ℃ | |

| Extend bonnet for reliable packing and sealing,extend stem length acc. to temperature | |

| Extend stem with drip pallet design acc. to temperature | |

| API6 24 Low fugitive emission packing | |

| Live load API 622 graphite | |

| Body cavity pressure relief system | |

| Floating ball type one way sealing | |

| Trunnion ball type Double isolation and block,bidirectional sealing | |

| Basic design | ball valves |

| FIRE SAFE | API 607 |

| ANTI STATICS | API 608 |

| Stem feature | Anti blow out proof |

| Bonnet Construction | Bolted bonnet |

| Ball type | Side entry or double block & bleed balls |

| Bore type | Full bore or Reduced Bore |

| Optional customize | NACE MR0175, MR0103, ISO 15156 compliance |

| ISO 5211 MOUNTING PAD Bare shaft | |

| Limit Switch | |

| Lock device | |

| ESDV service suitability | |

| ISO 15848-1 and ISO 15848-1 Low fugitive emission test | |

| Non-destructive test (NDT) API 6D, ASME B16.34 | |

| Third party inspection test report | |

| Documents | EN 10204 3.1 MTR Material test report |

| Pressure inspection report | |

| Visual and dimension control report | |

| Product warranty | |

| Valve operation manual |