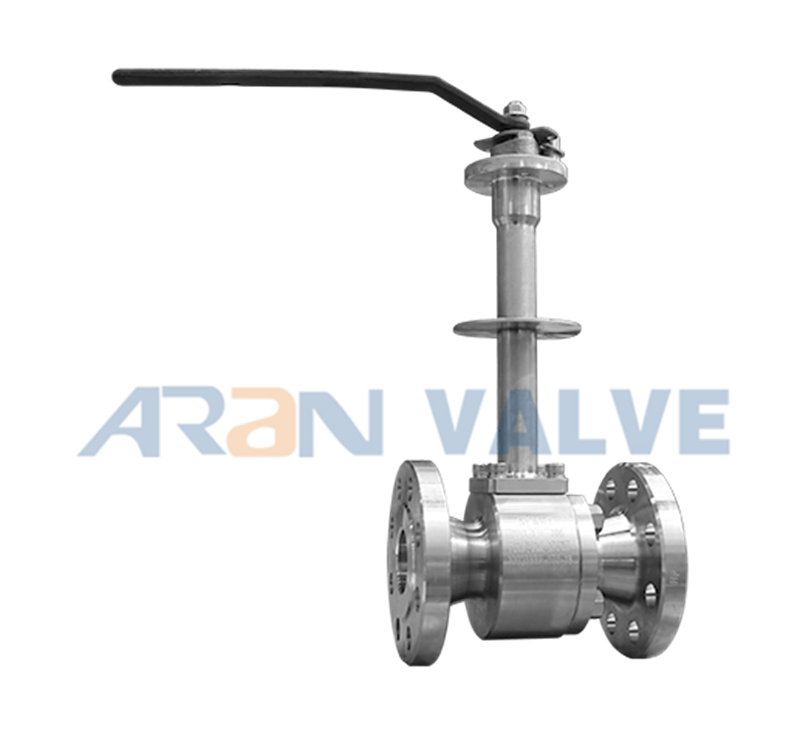

LNG Cryogenic Ball Valve Extend Stem for Low Temperature

ARAN Cryogenic ball valve design feature

The cryogenic ball valves has the special design structures meet to such service safety use.

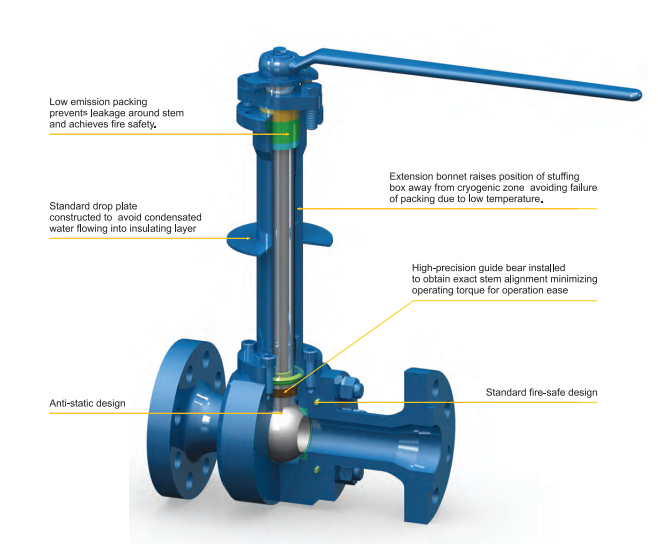

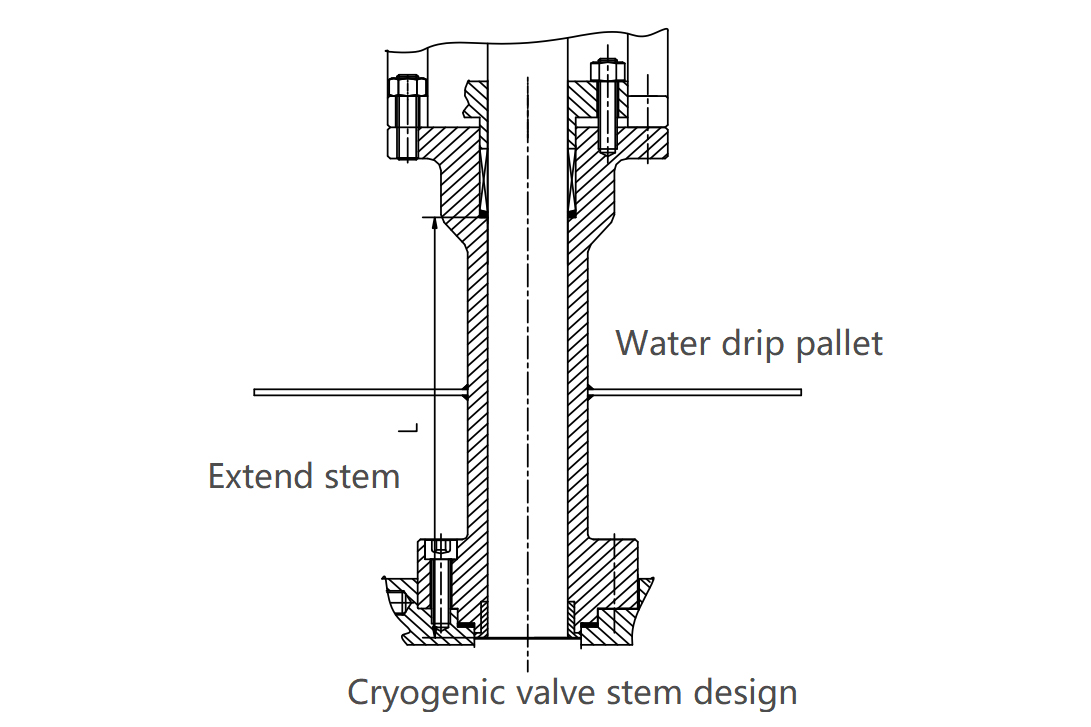

● The cryogenic valves designed with extended stem and water drip pallet in stem.

● The drip pallet can prevent the water vapor in the air from liquefying and then water flows to the valve surface and freezing, causing valve damage.They are applied to ensure the sealing performance of packing box and normal operation of ball valves . It also reduces the heat transferred from the outside to the inside of the device.

● Extend stem calculation according to SHELL SPE77/200/BS6364. The extend stem which is related to the thermal conductivity of the material, the thermal conductivity area, the surface heat dissipation coefficient and the heat dissipation area. The extend stem allows enough space for insulation material and ensures the stem packing sound sealed above 0℃.

● Low emission packing,prevents leakage around stem and ensure fire safe.

Fig. Extend stem and Drip Pallet

|

Main Parts Material |

||||

| BODY | LCB/LF2 | LC3/LF3 | CF8/F304 | CF8M/F316 |

| BALL | F304 | F304 | F304 | F316 |

| STEM | F304 | F304 | F304 | F316/XM-19 |

| SEAT |

PCTFE/RPTFE/PEEK |

|||

| PACKING |

PTFE/ GRAPHITE |

|||

| BOLTING |

A193 L7/A194 4 |

A193 B8/A194 8 | A193 B8M/A194 8M | |

Since cryogenic ball valves are used in low temperature conditions, the valve must be fully dried before delivery. The test medium in factory usually is be helium gas.If there is any liquid in valve body, the liquid will risk freeze at low temperature and will generate pressure on the internal components of the valve. The pressure will damage the valve sealing and pipeline damage risk. It’s also the reason why the cryogenic ball valve valve is replaced by the air pressure test instead of hydraulic test on site test. The construction site test facility is quite limited and the valve need be strictly dried before use.

Application

ARAN Cryogenic ball valves designated in highest performance and produced in strictest quality, can meet the highest standard cryogenic service,and wildly applied for safety transportation for processing,storage,shipment and distribution of ethylene,Liquid Nitrogen, Oxygen, LPG, Liquefied Natural Gas (LNG) and other low temperature liquefied gases.

As an efficient and storable clean energy, LNG has shown broad development prospects in all aspects of the industrial chain. Cryogenic ball valve is most demanding valve in the cryogenic liquid storage and transportation equipment system. It has the advantages of flexible switching, reliable sealing, safety and stability etc.

Crygenic Treatment And Test

The valve parts for cryogenic service need do the cryogenic treatment to make sure the valve material performance will suitable for low temperature.

The cryogenic treatment is the process of putting valve parts to low temperatures by medium nitrogen -196 ℃ in order to remove residual stresses and improve wear resistance in steels.

ARAN cryogenic treatment for ball valve part and cryogenic test for finished valve .

| Production Range | Cryogenic floating ball valve |

| Size | NPS 1/2″~8″ (50mm~200mm) |

| Pressure | ASME Class150~600LBS (PN16~PN100) |

| Production Standards | API/ANSI/ASME/EN/DIN/BS/GB/GOST |

| Design & MFG code | BS6364/ SHELL SPE 770200 Low temperature valveAPI 6D/ASME B16.34 /ISO17292/ ISO 14313/BS5351 |

| Face to Face | ASME B16.10,EN558 |

| End Connection | FLANGE RF/RTJ ASME B16.5/EN1092-1/GOST 33259 ;BUTT WELD BW ASME B16.25 |

| Test & Inspection | ISO 15848/SHELL SPE 77/312 Low temperature leakage testAPI 598, API 6D,ISO5208/ISO 5208/EN12266/GOST 9544 |

| Material code | Low Temperature Carbon Steel -40℃ (ASTM A350 LF2/LF3, ASTM A352 LCB/LCC)Low Temperature Carbon Steel -101℃ (ASTM A350 LF3, ASTM A352 LC3)Stainless steel -196℃ (ASTM A182 F316/F316L/F304/F304L DUAL GRADE, ASTM A351 CF8M/CF3M,CF8/CF3) |

| Operation | Manual, Worm Gearbox, Pneumatic actuator, Electric actuator,Hydraulic-electric actuator |

| Special design | Cryogenic ball valves |

| low temperature to -196 ℃ | |

| Extend bonnet for reliable packing and sealing,extend stem length acc. to temperature | |

| Extend stem with drip pallet design acc. to temperature | |

| API6 24 Low fugitive emission packing | |

| Live load API 622 graphite | |

| Body cavity pressure relief system | |

| Floating ball type one way sealing | |

| Trunnion ball type Double bleed and block,bidirectional sealing | |

| Basic design | ball valves |

| FIRE SAFE | API 607 |

| ANTI STATICS | API 608 |

| Stem feature | Anti blow out proof |

| Bonnet Construction | Bolted bonnet |

| Ball type | Side entry or top entry or double block & bleed balls |

| Bore type | Full bore or Reduced Bore |

| Optional customize | NACE MR0175, MR0103, ISO 15156 compliance |

| ISO 5211 MOUNTING PAD Bare shaft | |

| Limit Switch | |

| Lock device | |

| ESDV service suitability | |

| ISO 15848-1 and ISO 15848-1 Low fugitive emission test | |

| Non-destructive test (NDT) API 6D, ASME B16.34 | |

| Third party inspection test report | |

| Documents | EN 10204 3.1 MTR Material test report |

| Pressure inspection report | |

| Visual and dimension control report | |

| Product warranty | |

| Valve operation manual |