- ARAN manufacture Trunnion Ball Valves is available in an extensive range of designs, materials, sizes and pressure classes and are in full conformance with international production standards ANSI, ASME B16.34, API 6D, ISO17292, GOST, DIN/EN specifications etc.

- Trunnion ball valve has large scale production scope Class 150~Class 2500, PN16~PN420, different materials are used to transport water/ steam/oil and gas industries, can be low temperature and high pressure application circumstances, suitable products like, nitric acid, acetic acid, oxidizing media, urea, etc.

- The trunnion ball valves are widely used in petroleum refining, long-distance pipelines, chemical industry, paper making, pharmaceuticals, water conservancy, electric power, municipal administration, steel and other fields etc.

What’s Trunnion ball valve definition?

What’s Trunnion ball valve definition?

- The trunnion ball valve is a quarter-turn valve and trunnion design means the ball assembly is supported by a lower support trunnion and and upper top stem in the ball valve chamber. This design called trunnion mounted ball valve or trunnion ball valve.

- The trunnion ball valve usually applied for the large size and higher pressure ball valve operations ,as well as reduce the valve torque for easy operation.

- The trunnion-mounted stem absorbs the thrust from the line pressure, preventing excess friction between the ball and seats, therefore the valve operating torque remain low at full rated working pressure.

How the trunnion ball valve seat sealing?

How the trunnion ball valve seat sealing?

- Sealing is achieved by spring loaded piston type seats which shut off flow when line pressure acts on the upstream seat. Automatic relief of cavity over pressure is assured due to the trunnion design in case of self-relieving seats . The ball is operated by a sealed spindle to which the operator is attached. Ball valves are intended to be used as on/off flow control devices and are not to be used to throttle fluid flow. The valves should always be either fully open or closed.

- Trunnion ball valve seats design have important design features for different application needs:

- ● SELF RELIEVING SEATS /SINGLE RELIEF SEATS(SPE) and DOUBLE PISTON EFFECT SEATS (DEP)

- ● DBB and DIB seats design

- The trunnion ball valve ball is fixed but the seats is flexible. The Seat has SELF RELIEVING SEATS/SINGLE RELIEF SEATS (SPE) and DOUBLE PISTON EFFECT SEATS (DEP) design. The SPE design is one way uni-directional sealing and DEP is bi-direction sealing, by API 6D/ISO 14313 define.

- ARAN use trunnion ball valve designed seats single relief seat SPE-SPE and double block and bleed DBB as the standard produce. But the other types seats design also available upon specific request.

Single Piston Effect Seat Design features

Single Piston Effect Seat Design features

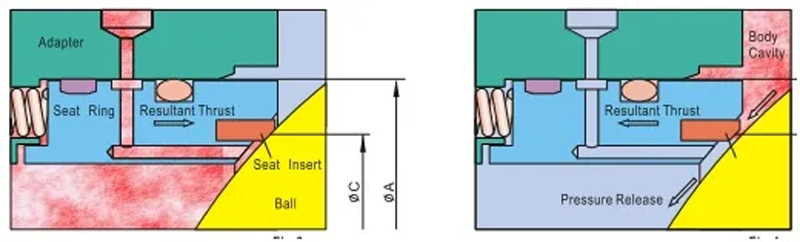

- Seats of the ball valves are pressed on the ball by means of spring load.

- As the body cavity pressure increases than the spring load, the seats are pushed back and the pressure is released in the line. This is called a single-piston effect (the pressure in the body cavity is the only acting parameter) .Cavity relief to the downstream side, if both the ball valve seats are of single-piston effect design. Each seat is self relieving the body cavity over pressure to the line.

- Fig. : Single Piston effect Seat Design

Double Piston Effect Seat Design features

Double Piston Effect Seat Design features

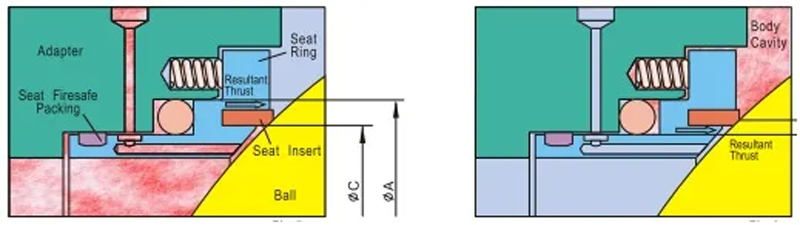

- In this seat design, medium pressure, as well as the body cavity pressure, creates a resultant thrust that pushes the seat rings against the ball. This is called a double piston effect (the pressure in the pipe & that in the body cavity both are acting parameters).Ball Valves with this design require a cavity pressure relief device to reduce the body cavity pressure.

- Fig. : Double Piston Effect Seat Design

Trunnion Ball valve DBB and DIB seats design definition

Trunnion Ball valve DBB and DIB seats design definition

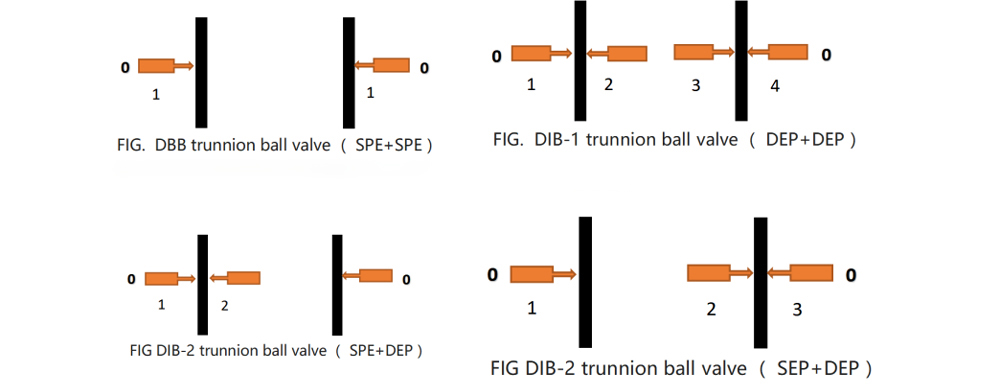

- ● DBB ball valve (double block and bleed ball valve)

- DBB ball valves to be one single valve with two unidirectional seats. This double block and bleed valve seals against pressures from both sides of the valve. This valve does not provide positive double isolation when only one side is under pressure.

- A DBB ball valve can be consider as a valve with two single piston effect (SPE) seats.

- ● DIB ball valve (double isolation and bleed ball valve)

- DIB ball valve is one single valve with two bidirectional seats. This double isolation-and-bleed valve provides an additional seal against pressure from only one side.This DIB feature can be provided in one direction or in both directions. The valve provides double isolation from pressure at both ends of the valve but cannot relieve body cavity pressure past the seats.

- The DIB feature can be provided in one direction or both directions.

- A valve with two double piston effect (DPE) seats has double isolation and bleed (DIB-1) design. A valve with one SPE seat and other DPE seat is a DIB-2 design valve. A DIB-2 valve will have a preferred installation direction.