- ARAN trunnion mounted top entry high performance ball valves are engineered to standards like API 6D, ASME B16.34, ISO 17292 and others on request.

- Top entry ball valves has the single union body with two paths, and a ball from top entry, and all the trim assembled from top entry, the bonnet from top side. Top entry ball valve structure union body not split body and trim top entry design has less in line paths way leakage and in line maintenance access into trim without removal valve for the pipeline. The top entry ball valves usually used in application that require a minimal disassembly for in-line maintenance.

Design features:

Design features:

- Top Entry, Full/Reduced Bore, Bidirectional/Unidirectional,

- Self Relieving, Anti blow out stem, Anti static device, Fire Safe, double block and bleed

- Carbon Steel, Low temperature Steel (LTCS)

- Low Alloy Steel, Stainless steel, Duplex, Super Duplex

- Nickel Aluminium Bronze etc

- Soft Seat insert: PTFE, RPTFE, PCTFE, PEEK, DEVLON, NYLON

- Metal Seat: TCC, TC, STL, NI60

- Special features:

- NACE Requirement, Piggable, Equalizing hole, Extended stem, Position indicator, Limit switch

- End connection:

- Flange RF / RTJ ends, Butt welded ends

- Available Standards and codes:

- API, ASME, ANSI, ISO, BS, GOST, DIN/EN, GB, JIS, NACE, API F6A, SIL, PED, EAC

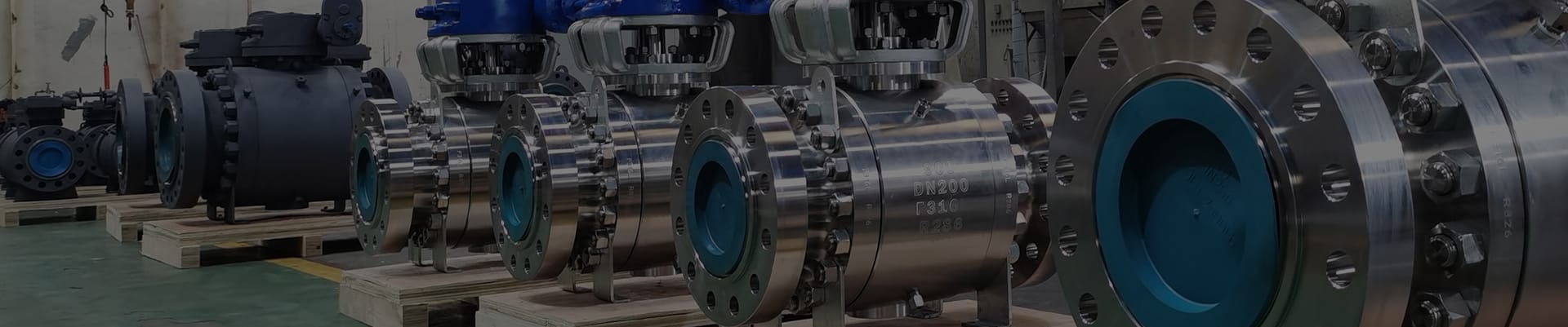

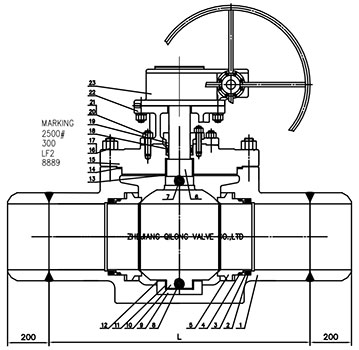

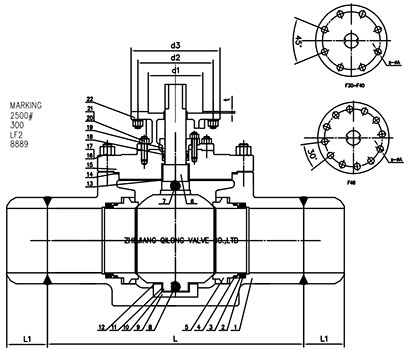

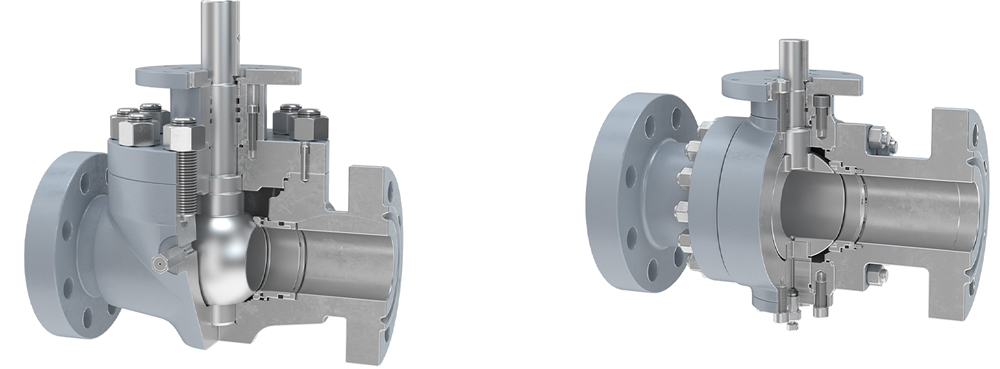

- ● Fig. Top entry ball valve cast steel material VS Top entry ball valve forged steel material

- ● Butt weld end top entry ball valve

- ● The welded end structure is adopted, which is installed on the pipeline and is not affected by the stress of the pipeline, which reduces the external leakage point and ensures the reliability of sealing.

- ● Fig. Butt weld end top entry ball valve gear box operation and ISO top flange ready for actuator

Top entry ball VS Side entry ball valve

Top entry ball VS Side entry ball valve

- Top entry ball valves has the single union body with two paths,and a ball from top entry, and all the trim assembled from top entry, the bonnet from top side. Top entry ball valve structure union body not split body and trim top entry design has less in line paths way leakage and in line maintenance access into trim without removal valve for the pipeline. So the top entry ball valves usually used at an application that require a minimal disassembly for in-line maintenance.

- Top entry ball valves made from cast or forged steel material form, if by cast material it usually need do NDT test to make sure that there is no casting defect, and forged steel material just need UT is enough. Due to good quality control the top entry ball valve has good performance preferred to at high pressure application that require in-frequent maintenance .

- Side entry ball valves are valves that assembled its ball from the side part. The body usually assembled in two pieces or three pieces by bolting called bolted bonnet or bolted cover ball valve , or sometimes fully weld joint body called full weld ball valve , or sometimes thread body for small size ball valve.

- Top entrance ball valves are usually more costly than side entry valves and have longer lead times attributed to the casting operations used to produce the body.

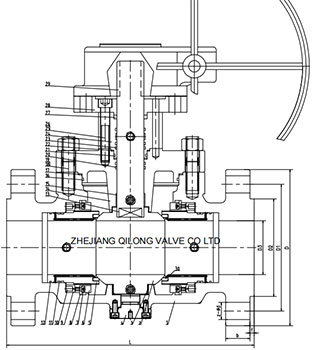

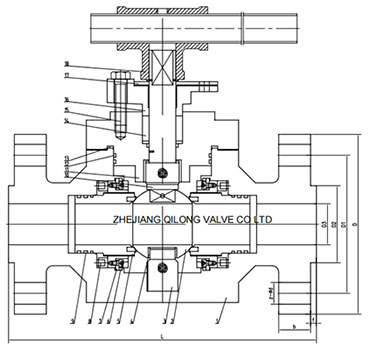

- ● Sectional Structure Drawing Top entry ball VS Side entry ball valve

- Top entry ball cast steel material Side entry ball valve forged steel material

Top Entry valves application

Top Entry valves application

- Top Entry valves are suitable for compression and re-injection systems, transmission pipelines, metering skids, Pig-launchers and receiving stations, Off- Shore and On-Shore platforms, gas storage and separations systems suitable for a wide range of high risk industry applications from severe abrasive and slurry to high temperature and cryogenic services, from sub-sea and LNG plants to topside installations.