API 6D Top Entry Ball Valve Forged / Cast Steel Material

Design Features

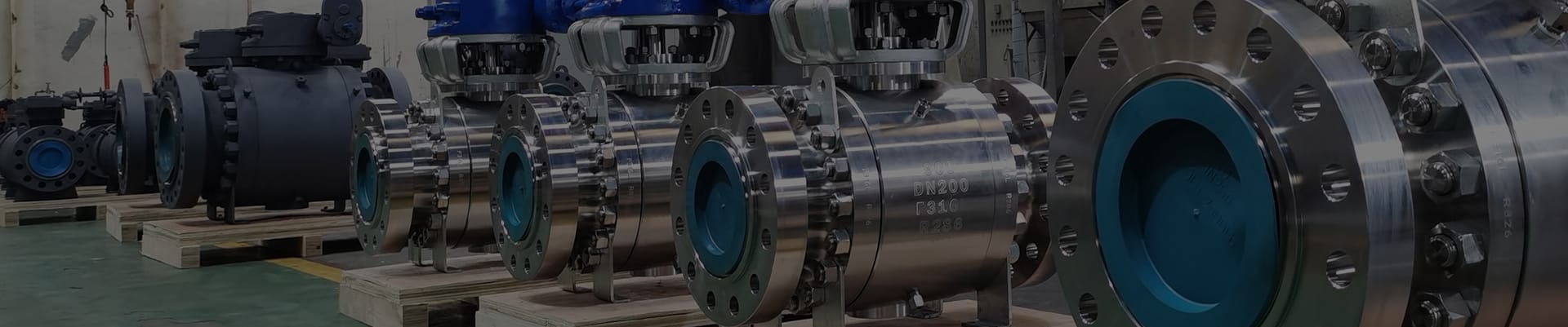

ARAN top entry trunnion ball are manufactured in forged or cast material in high performance and manufactured to international standards like API 6D, API 6A, ASME B16.34 and customer specific requirements on request.

Top-entry ball valves are easy to operate and maintain, simplifying in-line disassembly for trim inspection or repair, even when space is restrictive and requires limited maintenance.

The top entry ball valves also have excellent corrosion resistance and excellent sealing performance at high and low pressures.

The top entry ball valves can be applied for a wide variety of applications in the oil & gas, petrochemical, mining, and power industries when high quality, reliable valves are required.

The top entry ball will be produced in cast or forged steel material form acc. to valve pressure class and service media critical or not, we also produce the cryogenic service top entry ball valve by different medium and low temperature service.

Top Entry Ball Valves Production Range:

Material type Forged steel or Cast steel

carbon steel, LTCS, alloy steel, stainless steel, duplex steel, bronze, Inconel, Hastelloy, Monel, Incoloy etc.

Material code WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L

Ball type Top Entry Ball

Seat type Soft Seat (RPTFE, DEVLON, PEEK etc.) Customized Metal Seat available

Size NPS 2”~24” (50mm~600mm)

Pressure ASME Class150~2500LBS (PN16~PN420)

Operation Manual, Worm Gearbox, Pneumatic actuator, Electric actuator, Hydraulic-electric actuator

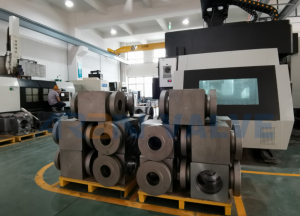

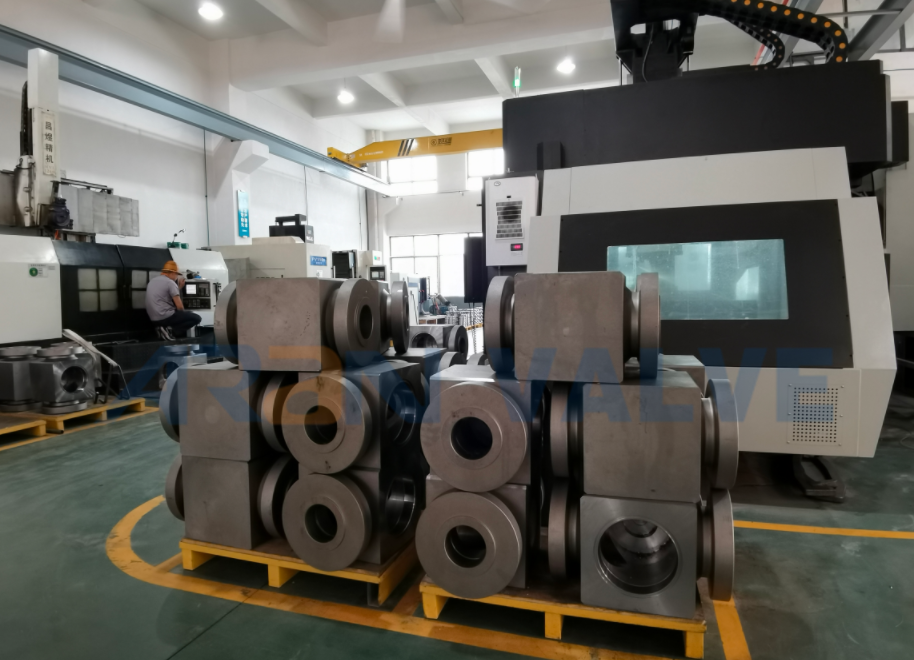

ARAN covers ranges of CNC machines, and all parts are machined by CNC lathes and machining centers, which ensure the shape and position tolerance and accuracy of the parts, with all CNC controls the valve tests and valve performance are improved tremendously.

The top entry ball valve forged material is in integrated forgings, which is more stable and reliable mechanically than casting under severe medium working conditions.

The top entry ball valve can also be produced in cryogenic specific for application in LNG and liquid nitrogen service.

With extended bonnet design, service low temperature -196°C. ARAN produce valve in live-load graphite API 622 and soft seat valve lip-seal sealing API 624 fugitive emission compliance.

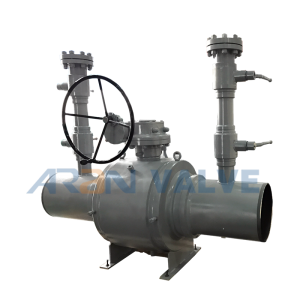

Top entry ball valve API6D

Class ANSI 600LBS RF size 20IN

Cast steel material WCB

Top entry ball valve API 6D

Class ANSI 900LBS size 4IN

Forged steel material A105

| Production Range | Top Entry Ball Valves |

| Material type | Forged steel or Cast steel: carbon steel,LTCS, alloy steel, stainless steel, duplex steel,bronze, Inconel,Hastelloy,Monel, Incoloy etc. |

| Material code | WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L |

| Ball type | Top Entry Ball |

| Seat type | Soft Seat (RPTFE,DEVLON,PEEK etc.) Customized Metal Seat available |

| Size | NPS 2”~24” (50mm~600mm) |

| Pressure | ASME Class150~2500LBS (PN16~PN420) |

| Operation | Manual, Worm Gearbox, Pneumatic actuator, Electric actuator,Hydraulic-electric actuator |

| Working Medium | WOG |

| Working temp. | Max 340℃, Low Temperature: -196℃~-100℃ |

| Production Standards | API/ANSI/ASME/EN/DIN/BS/GOST |

| Design& MFG code | API 608/API 6D/ISO17292/ ISO 14313/ASME B16.34/BS5351 |

| Face to Face | ASME B16.10,EN558,API6D |

| End Connection | FLANGE RF/RTJ ASME B16.5/EN1092-1/GOST 33259 ; |

| Test & Inspection | API 598, API 6D,ISO5208/ISO 5208/EN12266/GOST 9544 |

| Basic design | |

| FIRE SAFE | API 607 |

| ANTI STATICS | API 608 |

| Stem feature | Anti blow out proof |

| Ball type | Top entry |

| Floating ball type | one way sealing or bidirectional sealing |

| Trunnion ball type | Double bleed and block |

| Bore type | Full bore or Reduced Bore |

| Bonnet Construction | Bolted bonnet or full welded bonnet |

| Optional customize | NACE MR0175, MR0103, ISO 15156 compliance |

| ISO 5211 MOUNTING PAD Bare-shaft | |

| Limit Switch | |

| Lock device | |

| ESDV service suitability | |

| Bidirectional sealing to Zero leakage | |

| Extend stem for cryogenic service | |

| Non-destructive testing (NDT) to API 6D, ASME B16.34 | |

| Documents | Documents on delivery |

| EN 10204 3.1 MTR Material test report | |

| Pressure inspection report | |

| Visual and dimension control report | |

| Product warranty | |

| Valve operation manual | |

| Product of origin |