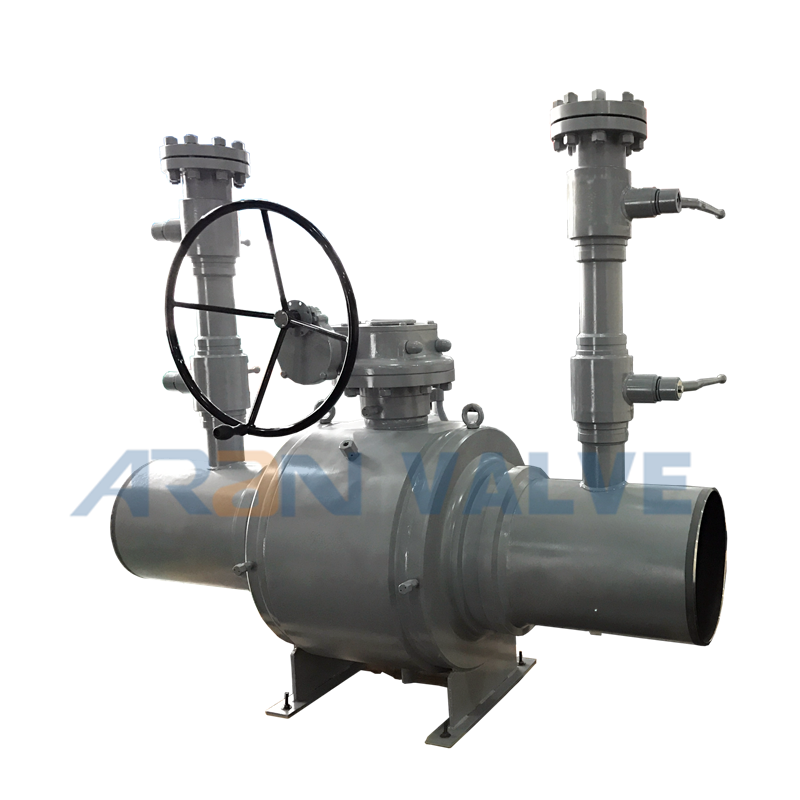

Fully Welded Body Ball Valve Butt Welded Ends For Oil And Gas

Fully Weld Ball Valve

The fully welded ball valve can be directly buried in the ground, without the need to build a underground valve house reduced the project cost. The length of the valve body and the height of the valve stem can be adjusted according to the construction and design requirements of the pipeline. The occasion with strict request external no leakage for transportation of toxic, harmful, flammable and explosive media, the full weld ball valve avoid the injury of personnel when operating the valve. The fully welded ball valve can be used reliably for a very long time under the condition of normal operation and use of the valve.

Fully welded ball valve means the ball valve is split body designed with the body assembly by full welding. Compared with conventional bolted bonnet body assembly, it has no leak point through bolt connection.The full welded body means the valves is impossible to do disassembly maintenance. So the full weld body ball valves used at underground or buried application where maintenance is not expected such as gas transmission, sub-sea application etc. For use in natural gas, crude oil, refined products transmission lines as well as in many other general industrial and oil& gas applications.

Russia GOST standard

fully weld ball valve

Underground

full weld ball valve

PE pup piece end

Full weld ball valve

Forged steel

butt weld ends

Underground service

Full weld ball valve

Extend pup piece with vent valve

| Production Range | Fully Weld Ball valve /Full Weld Ball Valve/Welded Ball Valve |

| Material type | carbon steel,Low temperature carbon steel LTCS, stainless steel, |

| Material code | A105, LF2, F304, F316, F304L, F316L, Seamless Steel pipe : ST37.8/ST 37.0/STEEL20# / P235GH /304/316 etc. |

| Ball type | Side entry Ball |

| Seat type | Soft Seat (RPTFE,DEVLON,PEEK etc.) Customized Metal Seat available |

| Size | NPS 2”~24” (50mm~600mm) |

| Pressure | ASME Class150~900LBS (PN16~PN160) |

| Operation | Manual, Worm Gearbox, Pneumatic actuator, Electric actuator,Hydraulic-electric actuator |

| Working Medium | WOG |

| Working temp. | |

| Production Standards | API/ANSI/ASME/EN/DIN/BS/GOST |

| Design& MFG code | API 608/API 6D/ISO17292/ ISO 14313/ASME B16.34/BS5351 |

| Face to Face | ASME B16.10,EN558,API6D |

| End Connection | FLANGE RF/RTJ ASME B16.5/EN1092-1/GOST 33259 ; |

| Test & Inspection | API 598, API 6D,ISO5208/ISO 5208/EN12266/GOST 9544 |

| Basic design | |

| FIRE SAFE | API 607 |

| ANTI STATICS | API 608 |

| Stem feature | Anti blow out proof |

| Ball type | Side entry Ball |

| Floating ball type | one way sealing or bidirectional sealing |

| Trunnion ball type | Double bleed and block,bidirectional sealing |

| Bore type | Full bore or Reduced Bore |

| Bonnet Construction | full welded bonnet |

| Optional customize | NACE MR0175, MR0103, ISO 15156 compliance |

| ISO 5211 MOUNTING PAD Bare-shaft | |

| Limit Switch | |

| Lock device | |

| ESDV service suitability | |

| Bidirectional sealing to Zero leakage | |

| Extend stem for cryogenic service | |

| Non-destructive testing (NDT) to API 6D, ASME B16.34 | |

| Documents | Documents on delivery |

| EN 10204 3.1 MTR Material test report | |

| Pressure inspection report | |

| Visual and dimension control report | |

| Product warranty | |

| Valve operation manual | |

| Product of origin |