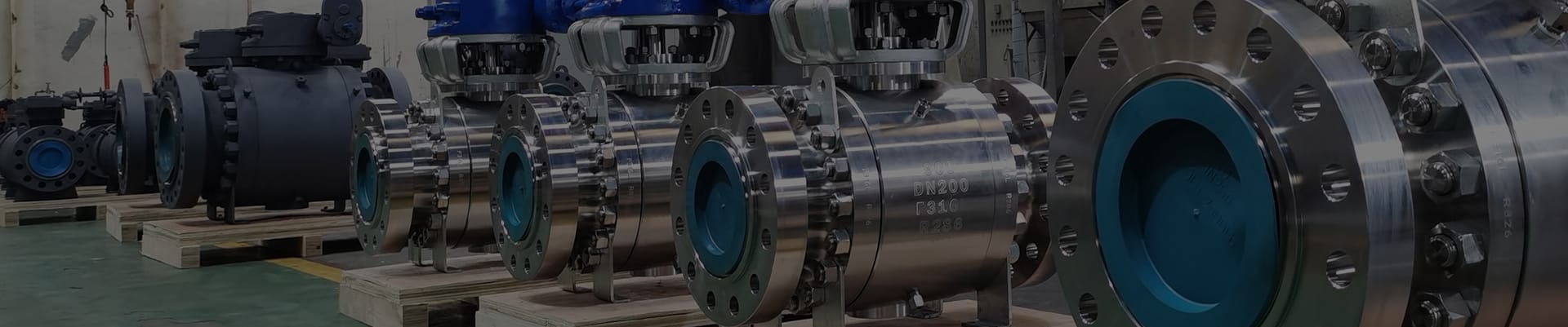

Trunnion Ball Valve Pneumatic Actuated Single Acting Type

Product Description

Pneumatic actuated Ball Valve, Double acting Pneumatic trunnion mounted ball valve, size 6in, class 600lbs RF, 3pc bolted bonnet body design, forged steel LF2 body, ball F316, Seat Devlon.

Pneumatic ball valve is the valve driven by pneumatic actuator. The pneumatic ball valve actuator is driven by the air source supply to rotate ball 90 degrees and a small torque to close or open tightly. The execution speed of the pneumatic actuator is very fast, and the fastest switching speed is 0.05 seconds/time, so it is also called a pneumatic quick cut-off ball valve. According to different functions, pneumatic ball valves are usually attached with various accessories, such as solenoid valves, air source treatment triples, limit switches, positioners, control boxes, etc, to achieve local control and long-distance centralized control, and the valve can be controlled in the control room, don’t need to go to the site or bring manual control at high altitude and dangerous place, which saves human resources, time and keep operator safe.

ARAN ball valve provide valve pneumatic actuator in different types.Usually we use China brand made, but if customer has special request, we can also use the international brand like Rotork and Auma. To choose the pneumatic actuator, there are two basic type of pneumatic actuator functions need to know.

● Doubling acting-Air supply the valve open and air lost,valve close position.

● Single acting-Air supply the valve open, and spring return close.

● Attachments complete with pneumatic actuator supply namely a solenoid valve, a limit switch, and a filter pressure reducing valve.

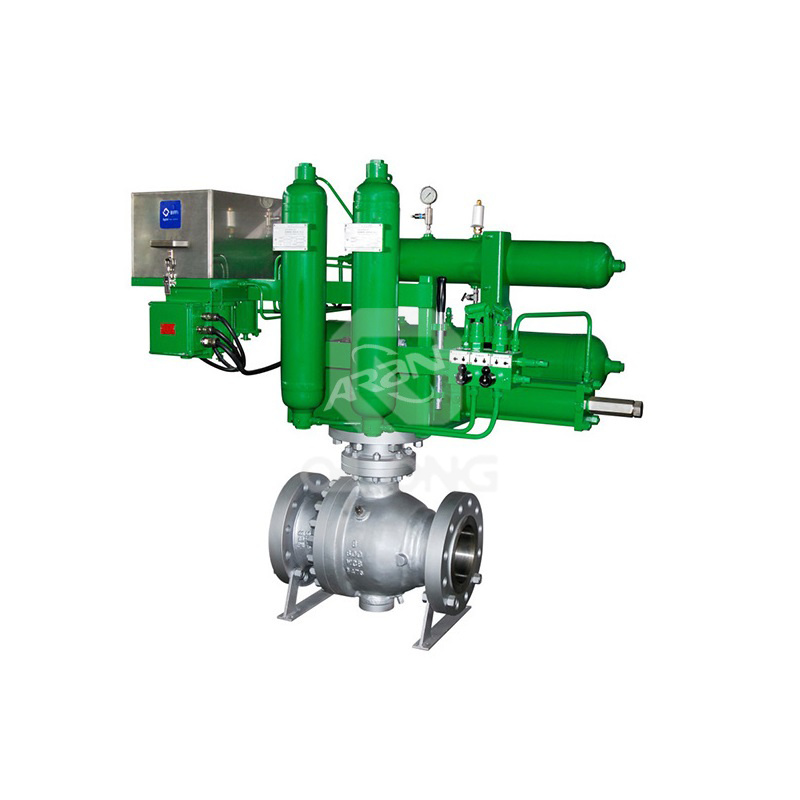

Gas-liquid linkage actuated Ball Valve

Pneumatic and Hydraulic Pneumatic actuated Ball Valve

Electric actuated ball valve

EN1092 flange connection, material duplex steel CD3MN

The gas-liquid linkage valve is powered by natural gas or independent gas supply, and the pressure oil is used as the transmission medium to drive the pipeline valve to open and close the actuator mechanism to ensure the safe operation of oil and gas pipelines.

The power source of the gas-liquid linkage valve is directly taken from the high-pressure natural gas in the main pipeline. After filtering, it enters directly the gas storage tank for storage through the high-pressure shuttle valve and single-phase valve (one way valve) without any decompression. Combined the integrated module unit, large flow, high pressure design technology, so that less control elements bear under high pressure, prolong the life of seals, reduce pipeline attachments part, reduce system leakage points, thereby improving the overall safety of the equipment.

Gas-liquid linkage is generally used in long-distance natural gas pipelines. Because the cost of compressed air or power supply in this place is very high, the pressure of natural gas in the pipeline is used as the power, and the compressed oil is used as the medium to open/close the valve. It has the advantage of no need electric power or air supply but it’s pipeline-self air source to realize the valve actuator operate in quick open/close or ESD.

The difference application choose of Gas-liquid linkage actuator and pneumatic actuator is the the gas pressure of the pipeline. The gas-liquid linkage is mostly used for high-pressure pipelines that require large torque and needs to take gas directly from the pipeline, and the pneumatic is mostly used for small-diameter pipelines with small torque or can provide instrument wind as power.

ARAN manufacture Trunnion Ball Valves are available in an extensive range of designs, materials, sizes and pressure classes and are in full conformance with international production standards ANSI, ASME B16.34, API 6D, ISO17292, GOST, specifications etc. The API 6D standard ball valve is most prevail in all industry standards, for the API standard is the highest valve standard in all kind of industrial application. Even some times the valves end connection will be changed in DIN/GOST/GB, the valve design will follow the API standard as the higher quality level.

|

ARAN BALL VALVE MAIN MATERIAL LIST |

||

|

BODY MATERIAL CAST & FORGED |

BALL/STEM |

SEAT |

|

A216 WCB/A216 WCC A182 A105/A105N |

A105+ENP/410 |

PTFE RPTFE DEVLON PEEK NYLON PPL Metal Seated |

|

A352 LCB/A352 LCC A182 LF2 |

LF2+ENP/17-4PH |

|

|

A351 CF8 A182 F304 |

F304/F304 |

|

|

A351 CF8M A182 F316 |

F316/F316 |

|

|

A351 CF3 A182 F304L |

F304L/F304L |

|

|

A351 CF3M A182 F316L |

F316L/XM-19 |

|

|

Super Duplex A995 4A CD3MN A182 F51 |

F51/A479 S31803 |

|

|

Super Duplex A995 5A CE3MN A182 F53 |

F53/A479 S31803 |

|

|

Super Duplex A995 6A CD3MWCUN A182 F55 |

F55/A479 S31803 |

|

|

A351 CK3MCuN,904L |

F904L/904L |

|

|

C95800,CA95500 |

F316/F316L |

|

|

Alloy-20 A351 CN7M, INCOLOY 800 |

Alloy-20 B473 N08020 |

|

|

Alloy-C276 A494 CW-12MW |

Alloy-C276 B574 N10276 |

|

|

Alloy-C22 A494 CX-2MW |

Alloy-C22 B574 N06022 |

|

| Specific | Details |

| Production Range | Trunnion Ball Valves |

| Body | Side entry 2pcs or 3pcs full weld or bolted body |

| Seat design type | Double block and bleed single piston seat as standard |

| Ball type | Trunnion mounted ball |

| Sealant injection | Stem and Seats sealant injection for soft seat,N/A for metal seat. |

| Material type | Forged steel or Cast steel: carbon steel, LTCS, alloy steel, stainless steel, duplex steel, bronze, Inconel, Hastelloy, Monel, Incoloy etc. |

| Material code | WCB/A105, LCB/LF2, CF8/F304, CF8M/F316, CF3/F304L, CF3M/F316L, C95800, 4A/CD3MN/F51, Inconel 625, Monel 400/CW12MW, etc |

| Soft seat material | Soft seat: PTFE/RPTFE/DELVON/PEEK/PPL |

| Metal seat material | Metal seated Hard coating material like CRC/TCC/STL/Ni60 |

| Size | NPS 2”~24” (50mm~600mm) |

| Pressure | ASME Class150~2500LBS (PN16~PN420) |

| Operation | Manual, Worm Gearbox, Pneumatic actuator, Electric actuator, Hydraulic-electric actuator |

| Working Medium | WOG |

| Production Standards | API/ANSI/ASME |

| Design& MFG code | API 608/API 6D/ISO17292/ ISO 14313/ASME B16.34/BS5351 |

| Face to Face | ASME B16.10, EN558 |

| End Connection | FLANGE RF/RTJ ASME B16.5; BUTT WELD BW ASME B16.25 |

| Test & Inspection | API 598, API 6D, ISO5208/ISO 5208 |

| Basic design | Ball valve |

| FIRE SAFE | API 607 |

| ANTI STATICS | API 608 |

| Stem feature | Anti blow out proof |

| Ball type | Side entry |

| Bore type | Full bore or Reduced Bore |

| Bonnet Construction | Bolted bonnet or full welded bonnet |

| Optional customize | NACE MR0175, MR0103, ISO 15156 compliance |

| ISO 5211 MOUNTING PAD Bare-shaft | |

| Limit Switch | |

| Lock device | |

| ESDV service suitability | |

| Bidirectional sealing to Zero leakage | |

| Extend stem for cryogenic service | |

| Non-destructive testing (NDT) to API 6D, ASME B16.34 | |

| Documents | Documents on delivery |

| EN 10204 3.1 MTR Material test report | |

| Pressure inspection report | |

| Visual and dimension control report | |

| Product warranty | |

| Valve operation manual | |

| Product of origin |