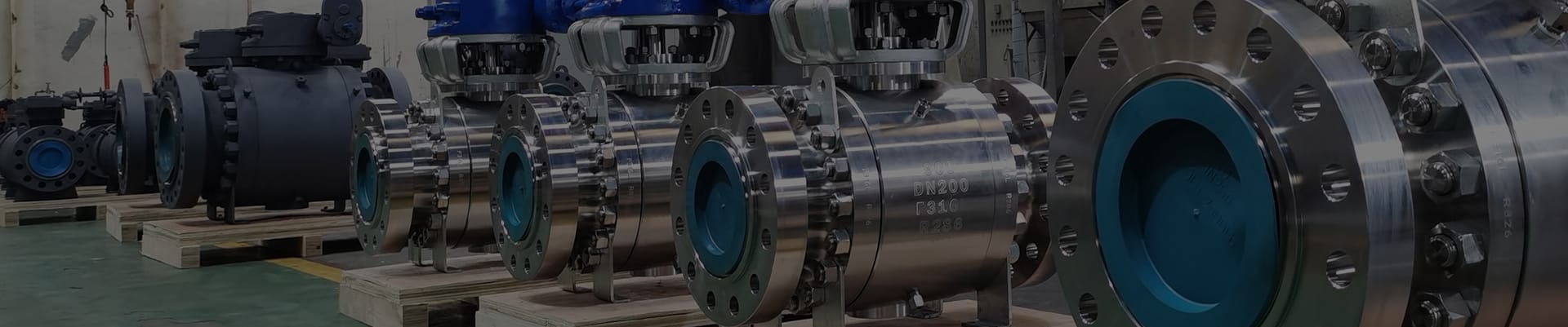

Multi Port Ball Valve Four Way/Three Way Ball Valve API 6D

Product Description

Multi port Ball Valve, Four Way Ball Valve, API 6D standard design, Material cast steel body and soft seated

Class size 20IN CL600 RF ends, MFG face to face, Gearbox operation

The four-way ball valve has the advantages of small assembly space, small fluid resistance, big flow capacity, and quick flow direction change. The ball valve has four sealing seats, so the ball has reliable sealing performance in any direction of rotation, and the position of the sealing ring can be adjusted to achieve the desired purpose. By rotating the valve operation 90°, can change any fluid direction open or close. The ball valve uses soft seat sealing material and has good and stable sealing performance, thus the maintenance is very convenient.

Four way ball valve Structure

LL port, T- port and L- port pattern, Straight Port pattern available

Four-way ball valves are used in oil, natural gas, coal and ore mining, refining processing and pipeline transportation systems; in chemical product processing, metallurgical, hydropower, thermal power and nuclear power power systems; in urban and industrial pipeline system. Water supply and drainage, heating, In the irrigation and drainage system etc. It is good choice for the circulation system of liquid, gas, dust, slurry and solid particle medium.

Application Case

The electric or pneumatic operating four-way flange ball valve is widely used in various pipeline systems for open and shut the flow, which makes the media transport to various points according to a predetermined program.

The four-way ball valve has important role in power station and petrochemical system. It is called two-way water supply valve in power station and called an air reversing switch valve in the petrochemical system.

The working principle of the process manifold and valve group is replaced by a four-way ball valve, which simplifies procedures,reduces costs,save space, easy operation, easy control, and has good synchronization.

Motorized four-way ball valve

| Production Range | Multi- port Ball Valves |

| Material type | Forged steel or Cast steel |

| Material code | WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L |

| Seat type | Soft Seated PTFE/RPTFE/DEVLON/NYLON/PEEKMetal seated Hard coating material like CRC/TCC/STL6/Ni60/STL |

| Size | NPS 2”~24” (50mm~600mm) |

| Pressure | ASME Class150~2500LBS (PN16~PN420) |

| Operation | Manual, Worm Gearbox, Pneumatic actuator, Electric actuator, Hydraulic-electric actuator |

| Working Medium | WOG |

| Working temp. | Max 350℃ |

| Production Standards | API/ANSI/ASME/EN/DIN/BS/GOST |

| Design& MFG code | API 608/API 6D/ISO17292/ ISO 14313/ASME B16.34/BS5351 |

| Face to Face | ASME B16.10,EN558 |

| End Connection | FLANGE RF/RTJ ASME B16.5/EN1092-1/GOST 33259 |

| Test & Inspection | API 598, API 6D, ISO5208/ISO 5208/EN12266/GOST 9544 |

| Basic design | |

| FIRE SAFE | API 607 |

| ANTI STATICS | API 608 |

| Stem feature | Anti blow out proof |

| Ball type | Top Entry |

| Bore type | Full bore |

| Bonnet Construction | Bolted bonnet or full welded bonnet |

| Optional customize | NACE MR0175, MR0103, ISO 15156 compliance |

| ISO 5211 MOUNTING PAD | |

| Limit Switch | |

| Lock device | |

| ESDV service suitability | |

| Non-destructive testing (NDT) to API 6D, ASME B16.34 | |

| Documents | Documents on delivery |

| EN 10204 3.1 MTR Material test report | |

| Pressure inspection report | |

| Visual and dimension control report | |

| Product warranty | |

| Valve operation manual | |

| Product of origin |